Our slitter and rewinder are used in various industries for decades. Due to the different requirements and degrees of automation, our designs are subject to continuous development.

We design and build the machine to meet your requirments to gently and effectively roll, wind up or finish your material.

Here are some examples of equipment we have built for our customers:

-

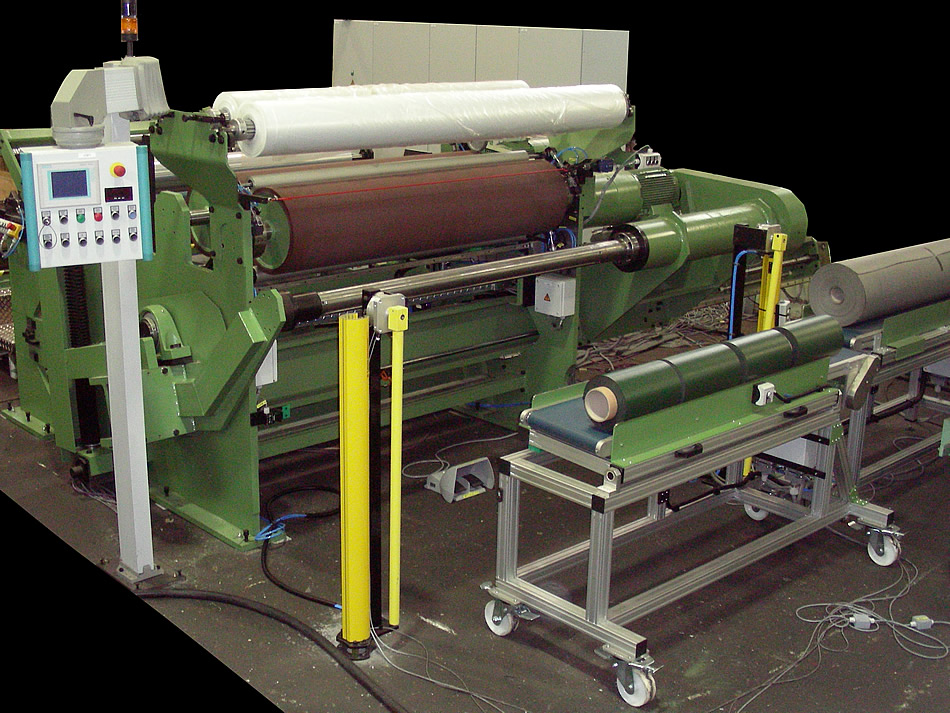

Slitter rewinder type UMV/1 1600

The machine is designed to rewind materials with sensitive surfaces, e.g. bonded leather, etc.. The rewind section is designed to produce small rolls (placed on a transport trolley) as well as large rolls (to be placed on a suitable pallet). There is no manual handling of the rewinding shaft, as it is pulled out of the cores by electric drive after the rolls have been lowered on the trolley or a pallet. The slitter can cut the web "wrapped" around the bottom knife shaft or barely touching the bottom knifes cut to minimise the strain on the material. With a pneumatically expanding knife shaft for the bottom knifes and pneumatic top knife holder the slitting positions can be changed quick and easy. The two edge trim winder are located below the slitter. The shaftless unwind is driven by electric drives for delicate web tension. The air powered chucks with different inner core diameters ensure a quick change of the mother roll. Special adapters to take wooden sleeves as well can be provided.

Technical data of machine displayed

Working width: 1.600 mm Web speed: 150 m/min Roll diameter unwinder: ø 1.600 mm Inner core diameter unwinder: ø 76 und 110 mm Slitting width: from 50 mm Inner core diameter rewinder: ø 76 und 110 mm Roll diameter rewinder: max. ø 1.200 mm

-

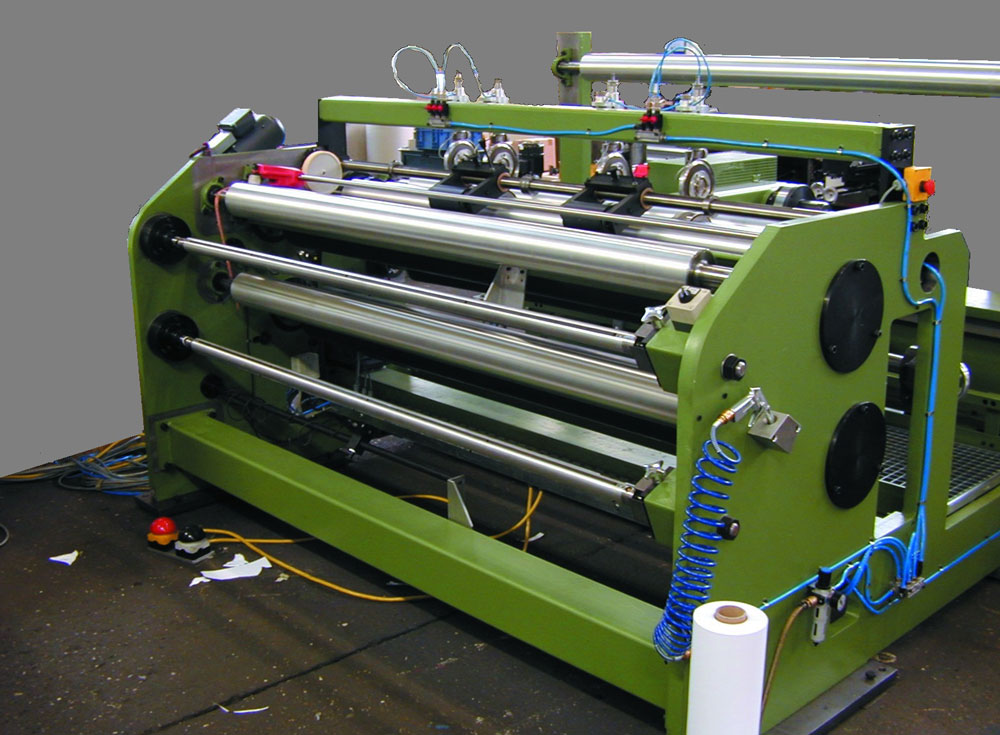

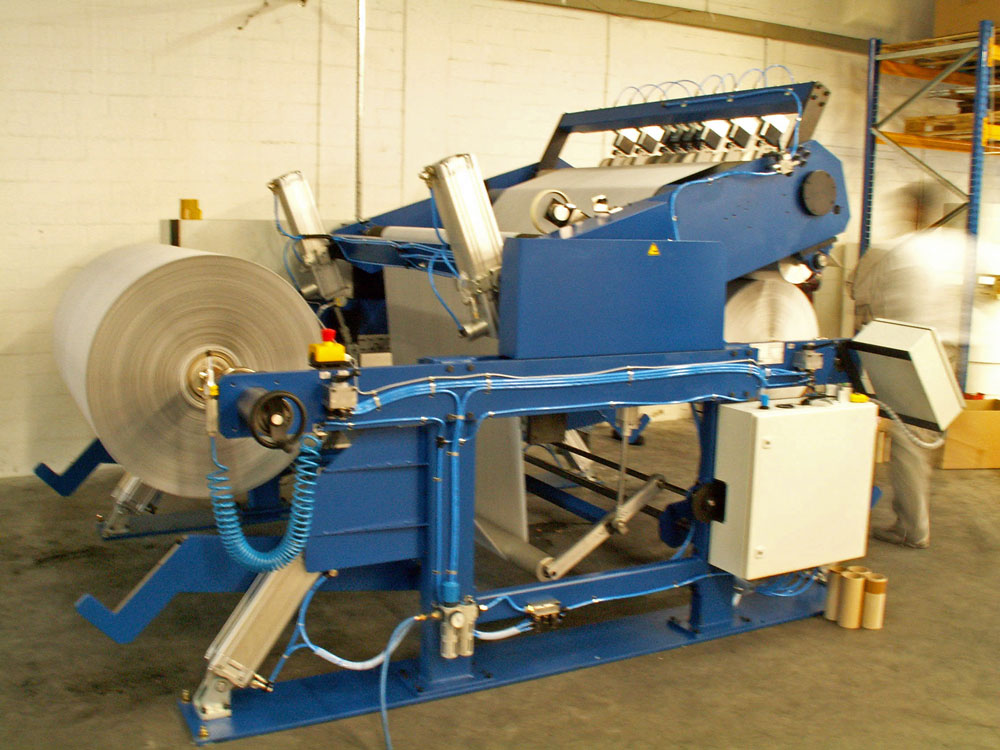

Slitter rewinder type UMV/2 1850 (short roll winder)

The machine is designd to rewinding a wide range of materials, e.g. paper, plastic film, textiles etc... The concept ensures a high output when producing short rolls (e.g. for plotter paper etc.) due to the simple handling. The slitter can slit narrow webs. With a pneumatically expanding knife shaft for the bottom knifes and pneumatic top knife holder the slitting positions can be changed quick and easy. The shaftless unwinder has air powered chucks with different inner core diameters ensure a quick change of the mother roll.

Technical data of machine displayed

Working width: 1.850 mm Web speed: 120 m/min Roll diameter unwinder: ø 1.300 mm Inner core diameter unwinder: 3'' und 6'' Number of slitts (min. 50 mm): any quantity Number of rewind axles: 2 Inner core diameter rewinder: ø 1'', 2'', 3'' und 6'' Roll diameter rewinder: max. ø 300 mm

-

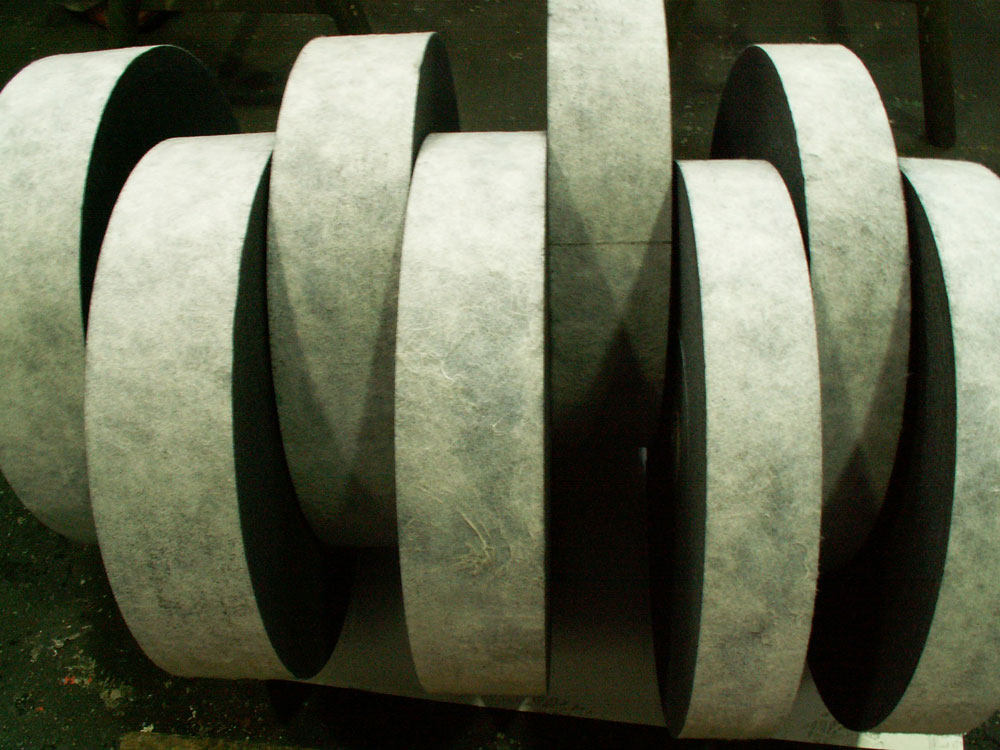

Slitter rewinder type ZW 1016

The slitter rewinder is used for rewinding different materials such as paper, nonwovens, filter materials (e.g. nonwoven webs with a middle layer of scattered carbon), etc.. The lifting device at the unwinder and the lowering device on the rewinder ensure a quick roll change without separate aids. The lifting device picks up the master roll directly from the floor or a suitable transport pallet. The lowering device places the finished rolls on the floor or on a suitable transport pallet. With a counter knife roller and pneumatic crush knife holder the slitting positions can be changed quick and easy.

Technical data of machine displayed

Working width: 1.600 mm Web speed: 50 m/min Roll diameter unwinder: ø 1.200 mm Core inner diameters unwinder (HID) an der Abrollung: ø 3'' und 6'' Side adjustment unwinder: +/-50 mm Slitting width: 45 mm Roll diameter rewinder: ø 1.000 mm Inner core diameter rewinder (HID): 3''

-

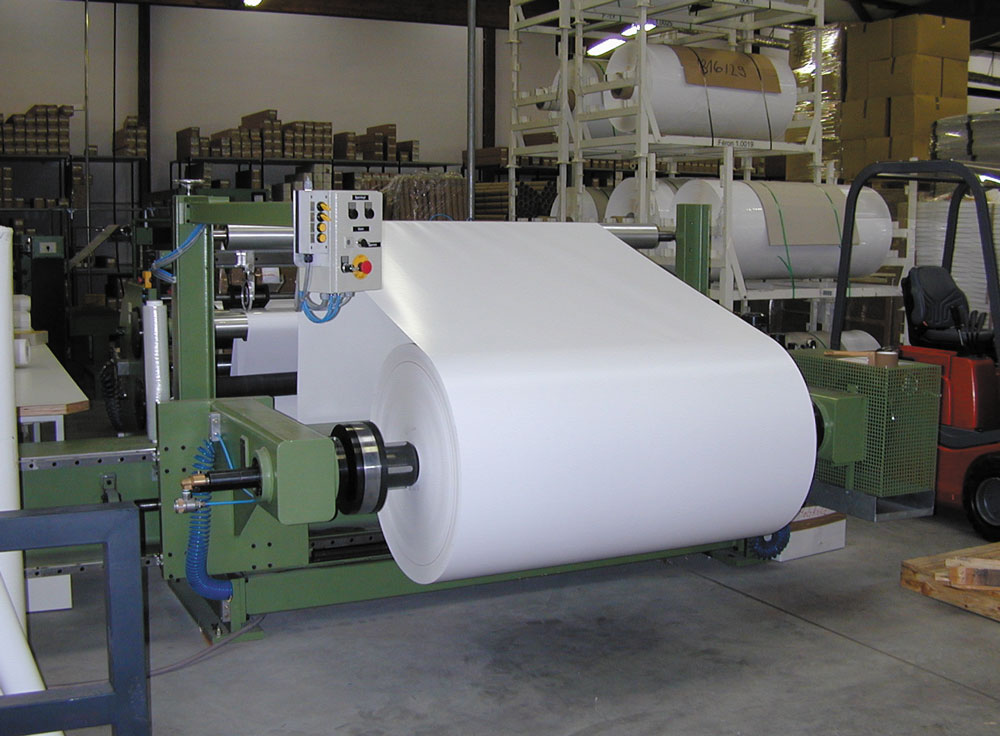

Slitter rewinder type ZW 2233

The machine is designed to rewind paper from tambour (papermachine winding axle) to tambour following the paper machine. The unwinder can take rolls on a tambour as well as big rolls on cardboard cores. Paper can be wound "core to drum". The big roll is picked up directly from the floor. The web is trimmed on the integrated slitter on both sides during the rewinding process. A 1.7 m long monitoring section allows the operating personal to approach and mask holes in the paper if necessary to prepare the web for the following coating on a coating machine.

Technical data of machine displayed

Working width: 3.160 bis 3.300 mm Base weight: 35 - 230 g/m² Web tension: 3.300 N Web speed: 1.200 m/min Roll diameter unwinder: ø 2.200 mm Roll weight: 15.000 kg Side alignement unwinder: +/- 30 mm Adjustment in web direction: +/- 15 mm Adjustment supportroller: +/- 20 mm Time to topspeed: 60 s Emergency stop: 30 s Pick-up unwind (for paper and cores): Core inner diameter unwinder: ø 12'' Roll weight: 4.000 kg

-

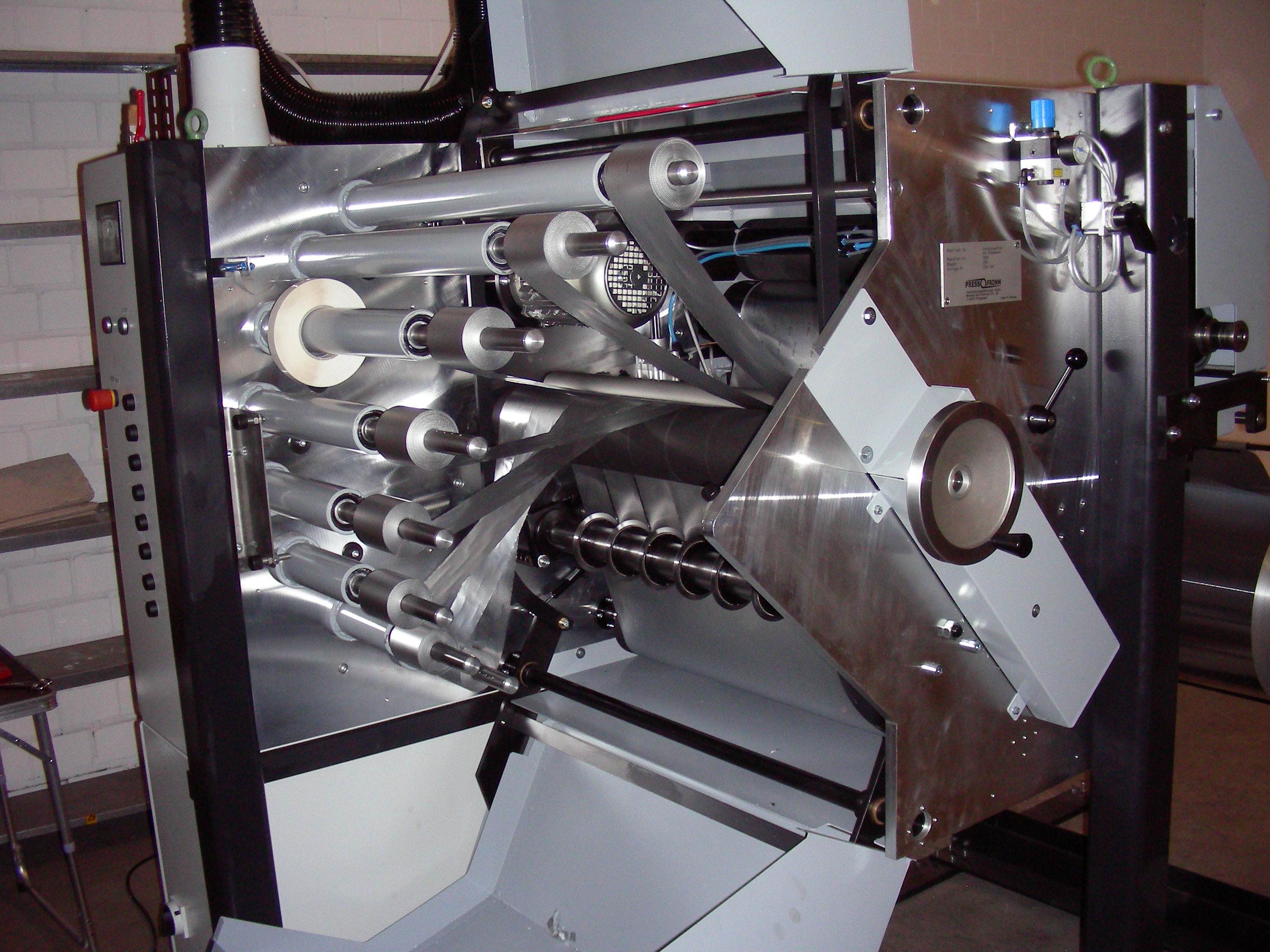

Unwinder and rewinder unit for narrow web

The unwinder and rewinder unit are used in a coating system. The web (e.g. a PETP film, etc.) may only be transported with the lowest possible tensile forces and narrow speed tolerances in order to achieve the most even coating possible. The rewinder unit is completely enclosed, due to the coating sensitivity to light. The units are designed according to ATEX guidelines.

Technical data of machine displayed

Working width: 74,2 mm Roll diameter unwinder: ø 550 mm Core inner diameter unwinder (HID): ø 6'' Web speed: 1-4 m/min Web tennsion: 50 N Protection type: Ex 1

-

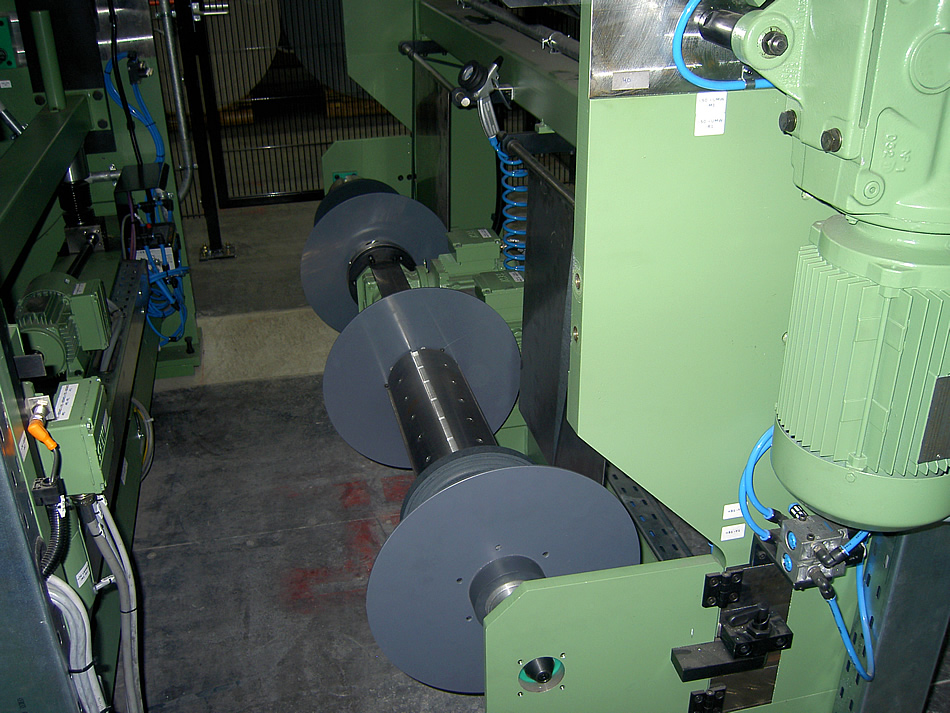

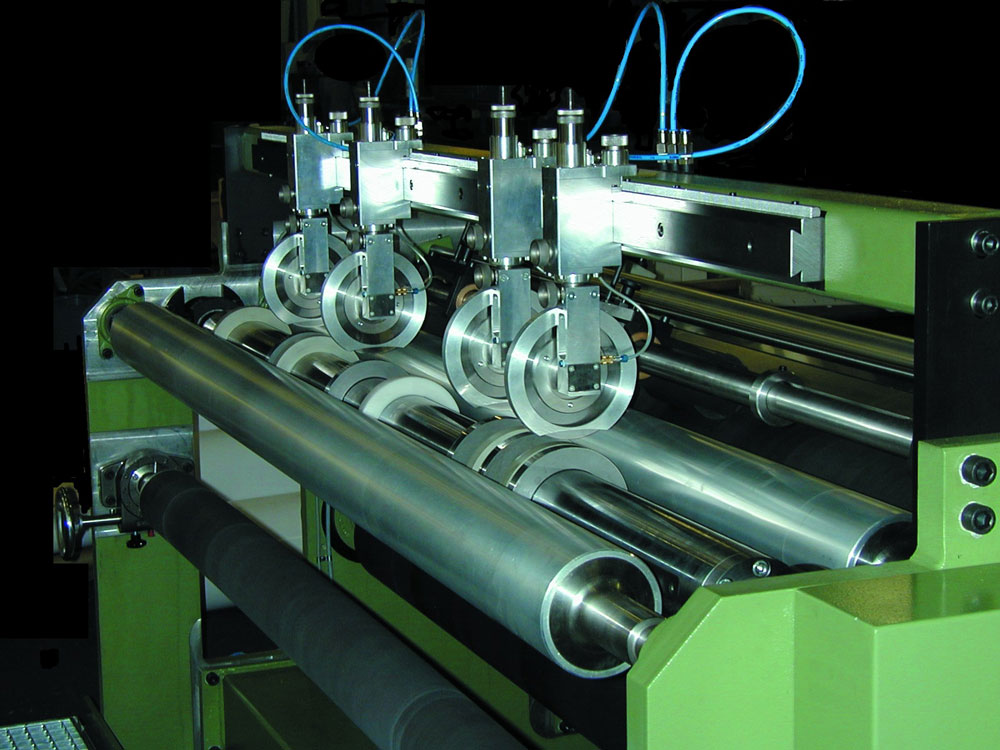

Slitter rewinder with embossing station

The machine produces short rolls of embossed aluminum foil. The short rolls are wound without cores. The embossing unit and slitter are integrated.

Technical data of the machine displayed

Working width: 720 mm Design speed: 200 m/min Roll diameter unwinding: ø 500 mm Inner core diameter: ø 6'' Winding axles: 8 rolls, coreless