-

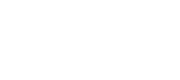

Double unwind (including integrated splicer) with web storage and pull station

The system concept ensures continuous unwinding of different web materials (e.g. nonwovens, foil, paper or similar), e.g. for a coating process. While one unwind is working, the other can be loaded with a new roll. The semi-automatic splicing device enables rapid roll changes. During the joining process the web must stand still. In this moment the following machine (e.g. for coating) is supplied with material web from the storage. Loading is via a mandrel carriage, which enables the roll to be pushed onto the cantilevered mandrel, which is relieved during unwinding by means of a pivoting support arm. Rolls with different inner core diameters can be unwound using appropriate adapters. In conjunction with the smooth-running rollers used, the associated traction unit allows the material web to be transported into the coating machine with a minimum traction force. The traction unit is a traction force separation for the web in the system.

Technical data of machine displayed

Working width: 800 mm Roll diameter: max. ø 1.000 mm Roll weight: 300 kg Core inner diameter: ø 3'', 5'' und 6'' Length storage: 32 m Web tension: 10-150 N/m -

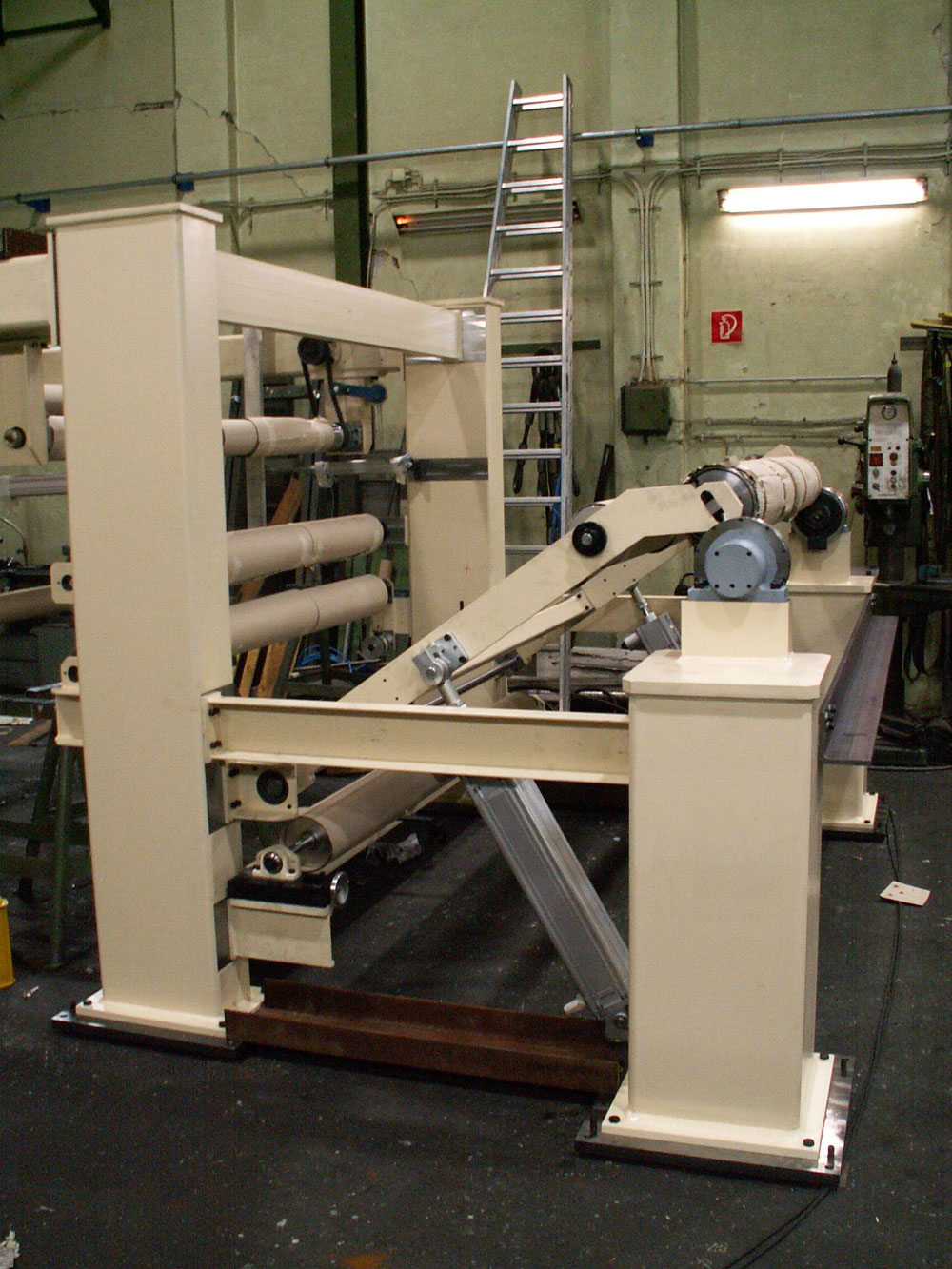

Laminating system

The system concept ensures unwinding of materials sensitive to tensile forces, that are be connected to each other on the entire surface by adhesive application or ultrasonic method. Materials used on the machine displayed are spunbond, meltblown, foam, paper, and similar. The rolls are held in safety chucks on expansion shafts. The webs are guided over easy-running rollers. The laminated web is wound up in a center rewinder with a pressure roller to influence the winding hardness.

technical data of machine displayed

Working width: 1.000 - 1.800 mm Web speed: 300 m/min No. of unwinder: 3 Roll diameter unwinder: ø 1.400 - ø 2.200 mm Roll weight: 2.000 kg Web tension unwinder: 10 - 360 N Roll diameter unwinder: ø 1.400 - 2.200 mm Roll weight: 2.000 kg Web tension rewinder: 50 - 720 N

Webdesign & SEO by mecksite